Think about the last time you had a deadline and were waiting for a print job to arrive. Maybe it was a batch of event brochures, training manuals, or direct mail pieces. You had the designs ready, the order placed, and then you waited, hoping there wouldn’t be a shipping delay, a misprint, or an unexpected rush fee. For many organizations, this back-and-forth raises a bigger question: Would it be better to invest in a production printer and bring this work in-house, or should we keep outsourcing?

It’s a decision businesses wrestle with more often than you might think. At STPT, we work with organizations of all sizes, from schools and churches to enterprise print shops, who are weighing this exact choice. The truth is, both in-house production printing and outsourcing have strengths and weaknesses. The right option depends on your volume, budget, priorities, and long-term plans.

This blog provides a clear and honest comparison of outsourcing and in-house printing, covering what each option really means in practice, their respective pros and cons, essential questions to consider before making a decision, and hidden costs that many businesses often overlook.

By the end, you’ll have the knowledge to make a decision that fits your business now—and sets you up for the future.

Table of Contents

- Option 1: In-House Production Printing

- Option 2: Outsourcing Production Printing

- Key Questions to Ask Yourself

- Print Quality & Turnaround: Then vs. Now

- Hidden Costs to Consider

- Conclusion: Choosing the Right Path

In-House Production Printing

When we talk about “in-house printing,” we mean investing in your own production printer, such as the Xerox PrimeLink C9200 Series or Xerox Iridesse Press, and handling jobs internally. Instead of sending projects to an outside vendor, you run them yourself, from short runs to high-volume campaigns.

Pros of In-House Printing

- Cost control and transparency – No vendor markups, minimum order requirements, or shipping fees. You know exactly what you’re spending.

- Faster turnaround – Print on demand when you need it. Urgent projects no longer mean “rush fees.”

- Confidentiality – Sensitive files never leave your organization, reducing privacy risks.

- Flexibility – Run one brochure or one thousand. Experiment with custom jobs, variable data, or new formats without paying extra.

Cons of In-House Printing

- Upfront investment – Whether leasing or buying, production printers are a major purchase.

- Ongoing responsibilities – Operators need training, and you’ll need to factor in maintenance, service contracts, consumables, and additional finishing options.

In short, in-house printing gives you control, speed, and freedom. However, it also comes with responsibility.

Outsourcing Production Printing

Outsourcing means working with a commercial print vendor. You send them your files, they handle the printing, finishing, and delivery.

Pros of Outsourcing

- No upfront investment – You don’t need to buy or lease a press.

- Specialty capabilities – Commercial vendors often have access to highly specialized print techniques you may not need every day.

- Hands-off approach – Maintenance, staffing, and supplies are handled by the vendor.

Cons of Outsourcing

- Longer turnaround times – You’re at the mercy of vendor queues, shipping delays, and reprint schedules.

- Hidden costs – Rush fees, shipping charges, and minimum order requirements add up quickly.

- Less control – Quality can vary, mistakes can happen, and sensitive data leaves your organization.

For smaller organizations with occasional print needs, outsourcing may be the more practical choice. But for those with steady or sensitive workloads, it can be limiting.

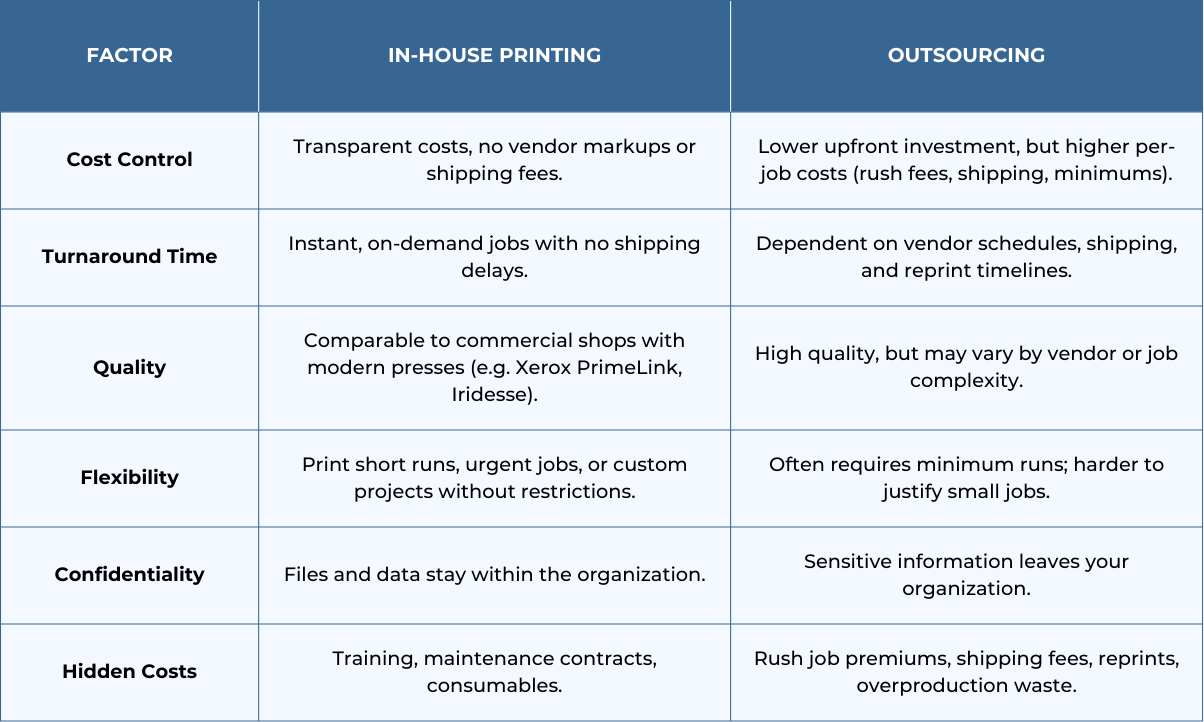

In-House Printing vs. Outsourcing: Quick Comparison

Key Questions to Ask Yourself

To help you decide which option makes more sense, ask yourself:

- How much do we spend on outsourcing each month (including rush fees and shipping)?

- What’s our average monthly print volume? (Hint: In-house often starts to make sense around 10,000 pages/month or more.)

- How important is confidentiality for our materials?

- Do we often need short runs or same-day turnaround?

- Are we looking to expand into specialty print applications that could generate revenue?

If your answers lean toward cost control, flexibility, speed, and security, then bringing production in-house could be worth exploring.

Print Quality & Turnaround: Then vs. Now

One of the most common objections to in-house printing used to be quality. Years ago, outsourcing was the only way to guarantee sharp, professional results. But this is no longer the case.

Modern production presses, like the Xerox PrimeLink C9200 Series and Iridesse Production Press, produce output on par with (and often better than) commercial shops. They can also print on a wide range of media and offer specialty options like metallics and fluorescents once exclusive to high-end vendors.

The difference is, with in-house, you get that quality instantly. You don’t have to wait; there's no shipping, and no “we’ll get to it next week.”

For a closer look at specialty printing enhancements, see our blog: How Do I Print in Metallics and Fluorescents? (What is CMYK+?).

Hidden Costs to Consider

While it’s tempting to only compare the upfront cost of a press to the invoice from an outsourced vendor, there are hidden costs to consider.

Hidden costs of outsourcing:

- Rush job premiums

- Shipping fees

- Reprint costs due to errors

- Overproduction caused by minimum order requirements

Hidden costs of in-house printing:

- Operator training and staff time

- Service and maintenance contracts

- Consumables like toner, paper, and specialty finishes

The real question isn’t just “Which is cheaper?” but “Which gives us more value, control, and flexibility for the long run?”

Choosing the Right Path

The choice to outsource or go for in-house production printing will ultimately depend on your organization. Outsourcing is often fine for low-volume or occasional print jobs. But for businesses with consistent needs, sensitive materials, or a desire to innovate with new applications, in-house printing is increasingly the smarter move.

Start by reviewing your current spend, monthly print volumes, and future goals. Then you can better determine whether a production printer will pay off now or whether outsourcing still makes sense for the time being.

To help you decide if a production printer is the right choice, and to see which machines might fit your needs, read our blog: Is a Production Printer Right for Your Business? + Costs.

And if you’re ready to explore options, take a look at our Guide to Xerox Production Print Solutions to learn about the presses, software, and finishing tools available today.