The number of configuration options and accessories available for printers has exploded in recent years.

One key way to tailor a machine to your printing needs is by adding a print finisher. This is a powerful tool that handles the final stage of document production, like stapling and hole-punching.

After 35+ years in the print industry, we know how critical finishers can be. But many people still ask:

- What is a print finisher?

- How much do they cost?

- Do I really need one?

We’ll answer these questions and more using Xerox machines as our primary example. But keep in mind, the insights apply broadly across the industry.

As a consumer, you need to know exactly what you’re getting into when you include a finisher because, spoiler alert, they cost money, and you don’t want to waste your money on a finisher you don’t need.

Let’s break it down.

What Are Print Finishers?

Print finishers are optional accessories that perform final-stage tasks, like stapling, punching holes, or making booklets, after a document is printed. They’re typically compatible only with larger, floor-standing printers (e.g., A3 models).

In Xerox’s lineup:

- Most VersaLink machines don’t support finishers, though there are a few exceptions. (Tip: Check with your vendor for specific VersaLink models that do.)

- Finishers become standard in the AltaLink and PrimeLink

- The more advanced the printer (e.g., production units), the more finishing options are available.

These accessories are especially popular in industries like education, law, finance, and healthcare, where high-volume, professionally finished documents are routine.

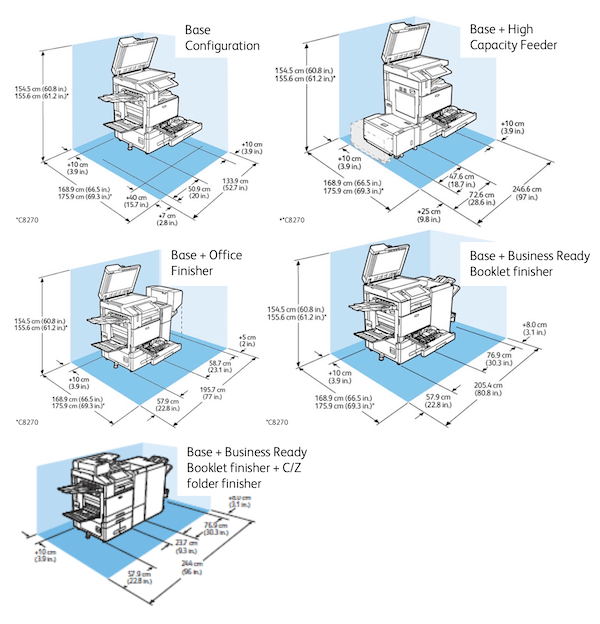

Note: Adding finishers changes your machine’s footprint. They require more space and sometimes an additional electrical outlet.

Read: Why Space & Electrical Requirements Matter for Printers

Here's a graphic showing how finishers increase space needs on the AltaLink C8270:

Top 3 Print Finishing Options for Xerox Printers

To give you a better understanding of print finishers, here are the three most common print finishers seen in the printer industry:

1. Stapler

Everybody knows what stapling is and has likely done it at one point in their life.

What some may not know, though, is that it’s not a function that comes standard with most printers. Instead, it must be added as a finishing option if you want your machine to automatically staple documents.

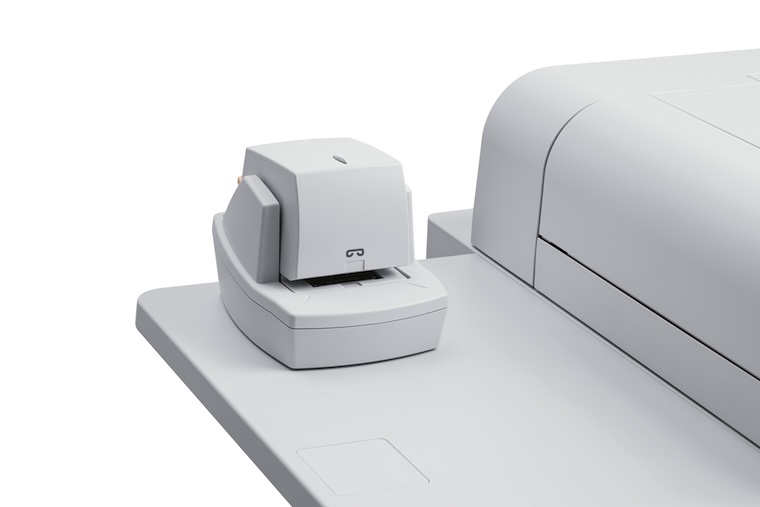

In Xerox’s lingo, the simple staple-finishing option is called the Convenience Stapler. This sits at the side of your machine for you to manually staple documents, but there are also more advanced stapling options, such as the Business Ready Finisher.

Below is the convenience stapler:

2. Hole-Punch

Another print finisher many consumers opt to include is hole-punching. There are multiple options in Xerox’s catalog.

Maybe the most popular finishing option from Xerox is the Business Ready Finisher. This includes both stapling and hole-punching and is exclusively for AltaLink and PrimeLink models.

There are also advanced hole-punch options that are better for production-style units, like the GBC FusionPunch II and GBC AdvancedPunch Pro. These are ideal for further automated hole-punching abilities.

Below is GBC AdvancedPunch Pro:

3. Booklet-Making

One important office task that finishers can perform is the creation of materials like booklets, pamphlets, brochures, and other specialty media.

Booklet-making is particularly popular among print customers, with multiple finishing options available:

- Business Ready Booklet Maker Finisher, which creates 64-page saddle-stitched booklets (2 to 16 sheets)—best for AltaLink machines.

- Xerox Production Ready Booklet Maker Finisher, which produces booklets of up to 200 pages and includes a 500-sheet top tray and 3,000-sheet stack tray—best for production machines.

- Plockmatic Pro 50/35 Booklet Maker, which can also produce booklets of up to 200 pages while doing face trimming, square fold, rotate crease, bleed trim and hand-feeding for sizes up to 12.6 x 9 in. It’s available for entry-level and large production machines.

In addition to the finishers discussed above, collating, trimming, cutting, and tape binding are other options that can be included as finishing options, among others.

Below is the Business Ready Booklet Maker Finisher:

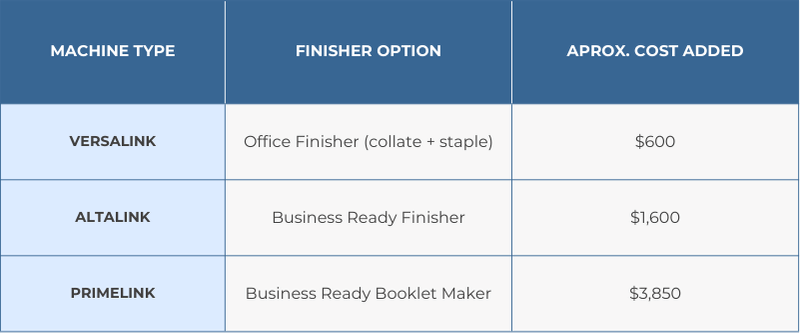

How Much Do Print Finishers Cost?

As mentioned in the introduction, print finishers are an added cost. The price largely depends on the machine you’re adding a finisher to, the finisher selected, and how many you’re adding.

Most consumers who purchase an advanced multifunction device add just one finisher, but that can vary depending on their goals.

Production machines can include multiple finishers, which will drive up the price of the machine.

Here's a quick breakdown:

In summary, adding more finishers to your machine, especially advanced ones, will increase the overall cost. However, cost should not stop you from adding a finisher if you truly need it to accomplish your daily business tasks.

The total cost of a printer can be broken down into monthly payments by leasing the machine instead of purchasing it outright. This is a popular option among consumers that are buying an advanced multifunction device or production unit.

Read our blog on leasing vs. purchasing a printer/copier to learn more about the two major options you have to pay for your next machine.

Should I Include Print Finishers?

That depends entirely on your needs.

Add a Finisher If:

- You frequently staple or hole-punch.

- You print at high volumes.

- You often produce booklets, brochures, manuals, or specialty prints.

Skip the Finisher If:

- You rarely need document finishing.

- Manual stapling is manageable.

- You’re working with a smaller desktop unit.

Industries like education, healthcare, and law almost always benefit from at least a basic finisher. Production shops will want advanced finishers for advanced print jobs.

Tip: Think about the type and volume of documents you produce each day before deciding.

If you print a lot and have a machine that can accommodate a finisher, it's generally a good idea to invest in at least a basic office finisher. This is because it can automate the process of finishing documents.

What Other Additional Accessories Can You Add to a Printer?

Print finishers are just one of the many optional accessories you can add to your printer to maximize your investment. Other optional accessories include:

- Envelope trays

- High-capacity paper feeders

- Extra paper trays and stands

- App-based tools to automate workflows

Apps vary by model and use case. They’re not for everyone, but can offer serious productivity boosts.

Printer apps are optional accessories and work in many different ways, depending on which app you choose, but most of them cost money and won’t be a fit for all businesses.

Read: Pros and Cons of Printer Apps

Ready to Enhance Your Printing Capabilities?

Use our interactive Product Configurator to:

- Customize your printer setup in real-time

- See how finishers affect size, features, and layout

- Understand what each finisher does

- Request a quote for your ideal configuration

Launch the Printer Configurator Now

Or contact our team to help guide your selection based on your workflow needs.