Margins in the print industry are razor thin. According to IBISWorld, commercial printing revenue has declined at a CAGR of 2.8% to about $76.7 billion over the past five years. That doesn’t mean print is going away, but print shops need to get smarter about the equipment they invest in if they want to stay profitable.

For pay-for-print shops, choosing a production printer can make or break the business model. The right machine can handle a wide range of jobs quickly, keep per-page costs low, and open the door to higher-value services. The wrong one, on the other hand, can eat into margins, slow down turnaround times, or even limit what you can offer your customers.

At STPT, we’ve worked with pay-for-print shops, in-plant operations, and marketing providers. We’ve seen the pitfalls of choosing a press based only on initial price, and we’ve also seen how the right match can transform a shop’s bottom line.

In this guide, we’ll walk through common mistakes to avoid, the top printers worth considering in 2025, what costs to watch out for, and the questions you should be asking before signing any contract.

Table of Contents

- The Biggest Mistakes Print Shops Make When Choosing a Press

- Signs It’s Time to Upgrade from Office Printers to a Production Press

- Best Printers for Pay-for-Print Shops in 2025

- Xerox PrimeLink C9200 Series

- Xerox PrimeLink B9100 Series

- HP Indigo 120K

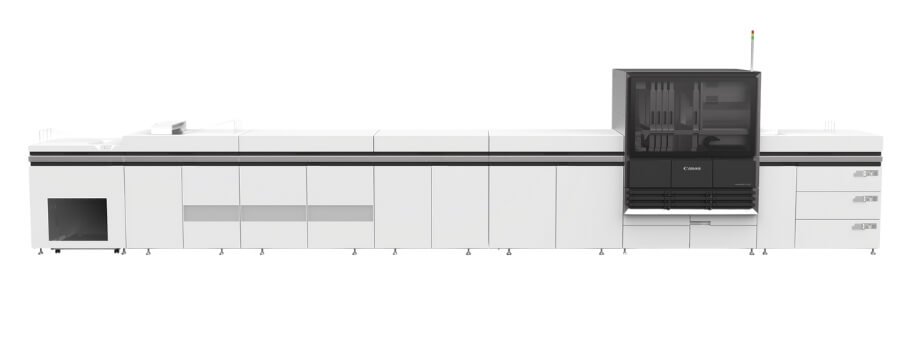

- Canon varioPRINT iX1700

- Konica Minolta AccurioPress C14010S

- Ricoh Pro C5400S/C5410S

- Total Cost of Ownership: What You Need to Know

- Questions to Ask Before You Sign a Contract

- What’s Changing in the Industry (Why It Matters Now)

- Conclusion: Matching the Right Press to the Right Shop

The Biggest Mistakes Print Shops Make When Choosing a Press

Before we talk about the “best printers,” let’s talk about what gets shops into trouble:

- Focusing only on purchase price. The cheapest option up front isn’t always the cheapest long term. Cost per click, service agreements, and downtime matter more than the sticker.

- Buying too much machine. Over-investing in a press that your shop can’t keep busy leads to wasted capacity and higher monthly payments that never pay off.

- Buying too little machine. On the flip side, a device that’s underpowered for your workloads will bottleneck jobs, hurt turnaround times, and frustrate customers.

- Ignoring usability and workflow. Today’s production printers integrate with software for prepress, job routing, and even variable data campaigns. Skipping those features limits growth.

- Skipping test prints. You wouldn’t buy a car without a test drive. Similarly, always run your real jobs on the press before committing.

Signs It’s Time to Upgrade from Office Printers to a Production Press

Many pay-for-print shops start small and rely on office MFPs to handle early jobs. However, at some point, these machines are not enough. Here are the red flags it’s time to step up to production-level equipment:

- You’re maxing out the monthly duty cycle of your current machines.

- Customers are asking for booklets, bound reports, or coated materials your office devices can’t produce.

- Deadlines are getting tighter, and you can’t keep up with turnarounds.

- Outsourcing certain jobs has become too expensive or too frequent.

If these sound familiar, it’s time to consider moving into production-class devices designed for shops like yours.

Related reading: Is a Production Printer Right for Your Business? + Costs

Best Printers for Pay-for-Print Shops in 2025

Not all presses are built for the same kind of shop. Below are some of the most relevant options on the market.

Xerox PrimeLink C9200 Series

Why it works for pay-for-print shops:

The PrimeLink C9200 Series is a series of versatile entry-level production presses that offer professional-quality color at an approachable price point. A PrimeLink is especially useful for shops that want to expand into more profitable services, like brochures, flyers, direct mail, and booklets, without jumping straight into the most advanced production presses.

Pros:

- Handles a wide range of media types, including heavyweight cardstock and long sheets.

- Produces high-quality, consistent color output across jobs.

- Offers flexible finishing options (booklet making, stapling, trimming) so shops can expand their service offerings.

Cons:

- Color toner costs can add up for very high-volume runs, so margins need to be managed carefully.

- Adding finishing modules and feeders increases both footprint and cost, which may be limiting for smaller spaces.

Explore the Xerox PrimeLink C9200 Series

Xerox PrimeLink B9100 Series

Why it works for pay-for-print shops:

For shops that need a workhorse in black-and-white, the PrimeLink B9100 Series is an incredibly reliable option. It’s ideal for transactional work, training manuals, course packets, and other jobs where volume and turnaround speed matter most.

Pros:

- High monthly duty cycle (up to 700,000 pages), making it ideal for nonstop workloads.

- Produces sharp, crisp black-and-white output at professional quality.

- Wide range of finishing options, including booklets, binding, and stacking, supports diverse applications.

Cons:

- Monochrome-only, so it can’t expand into color-driven services.

- Large footprint with optional modules may not fit easily into smaller spaces.

HP Indigo 120K

Why it works for pay-for-print shops:

The HP Indigo 120K is built for shops chasing offset-level quality with the flexibility of digital. It’s designed for high-value applications where premium quality justifies higher pricing, such as luxury marketing pieces, packaging, and photobooks.

Pros:

- Predictable budgeting with pay-per-click pricing.

- Automation reduces labor needs and boosts efficiency.

- Delivers offset-level quality that attracts premium jobs.

Cons:

- Higher per-page cost compared to toner presses.

- Requires trained operators to get the most out of the machine.

Canon varioPRINT iX1700

Why it works for pay-for-print shops:

The Canon varioPRINT iX1700 is an inkjet press geared toward long runs and streamlined production. It’s especially useful for shops that want to reduce energy costs and minimize maintenance downtime.

Pros:

- Inkjet technology lowers energy use and ongoing maintenance.

- Consistent, reliable output for long-run jobs.

- Competitive running costs make it efficient for sustained workloads.

Cons:

- Media setup requires extra operator time.

- Training is needed to get jobs running smoothly.

Konica Minolta AccurioPress C14010S

Why it works for pay-for-print shops:

The Konica Minolta AccurioPress C14010S is a versatile production press designed to appeal to shops that want to add creative services. Its specialty color capabilities allow for more unique applications that command higher prices.

Pros:

- Supports specialty colors like white ink to expand offerings.

- High speed and strong paper handling for demanding workloads.

- Consistent image quality across a variety of media types.

Cons:

- Specialty supplies increase consumable costs.

- Operators need training to manage advanced color features.

Total Cost of Ownership: What You Need to Know

A production press is more than just a piece of hardware. It’s whole ecosystem of consumables, service, and uptime.

Here are factors that can affect your real costs:

- Cost per click: The per-page cost of toner and service combined.

- Service agreements: What’s included (and what’s not).

- Downtime risk: A cheaper machine that’s often down is far more expensive than a reliable one. Learn more about the cost of printer service here.

- Scalability: Can the press grow with your shop, or will you outgrow it quickly?

For example:

- The Xerox B9100 Series has one of the lowest monochrome costs per page on the market.

- The C9200 Series offers a strong balance of affordability and flexibility for color output, making it ideal for shops expanding services.

- Premium presses like the HP Indigo offer unmatched quality, but at much higher costs that only make sense with consistent demand.

Questions to Ask Before You Sign a Contract

- What’s the real monthly duty cycle of the machine?

- What’s included in the service plan (parts, labor, consumables)?

- What is the actual cost per page?

- Can I add or upgrade finishing options later?

- Who services the machine locally, and how fast is their response?

- Can I see my actual jobs printed before making a decision?

Asking these questions upfront can save your shop from costly mistakes later.

Conclusion: Matching the Right Press to the Right Shop

The “best” production printer for pay-for-print shops goes beyond brand loyalty. It’s crucial to find the right fit. A small local shop may thrive with a Xerox PrimeLink C9200, while a creative agency may push the boundaries with an HP Indigo. The key is balancing what your clients demand, what your budget can support, and how much room you want to leave for growth.

At STPT, we’ve helped dozens of print shops make this decision. And time and again, the right choice comes down to matching real-world needs with the press built to handle them.

Explore the Xerox PrimeLink C9200 Series

Ready to see how the PrimeLink C9200 could fit your shop? Configure finishing options, see specs, and request a quote directly on our landing page.

Explore the Xerox PrimeLink C9200 Series

If you're still weighing your options, check out our guide: Which Xerox Production Printer Is Right for You?