Have you ever watched your office’s color laser printer in action, curious about how it transforms a digital file from your laptop into a vibrant, complete page in just moments? Many people use these machines daily, yet few truly understand the complex process happening inside.

As print vendors who work with everything from small desktop units to high-volume production printers, we live and breathe this stuff. We’ve set up, maintained, and troubleshooted enough color laser printers to know them inside and out, literally.

In this guide, we’ll walk you through the step-by-step process of how a color laser printer works, explain the key components, clear up some common myths, and show you why these machines are so valuable for offices and schools. By the end, you’ll have a clear picture (pun intended) of what’s going on behind that sleek exterior. Plus, you might even be ready to choose the right one for your workspace.

Interested in how laser printers have evolved? Check out our blog on The Evolution of the Laser Printer.

Step-by-Step: How a Color Laser Printer Works

1. Getting the Image from Your Device

It all starts when you hit Print. Your computer, phone, or the printer’s own scanner sends the digital file to the printer’s xerographic processing board. This is essentially its brain. This board controls image input and perfectly times every part of the print process.

2. Cleaning Cycle

Before anything else, the printer gives itself a quick tune-up. It spins its drums and transfer belt to clear away any leftover toner or dust. This ensures your print comes out crisp without ghost images from previous jobs. (Some monochrome models skip the transfer belt entirely and print directly from the drum to paper.)

3. Charging the Drum

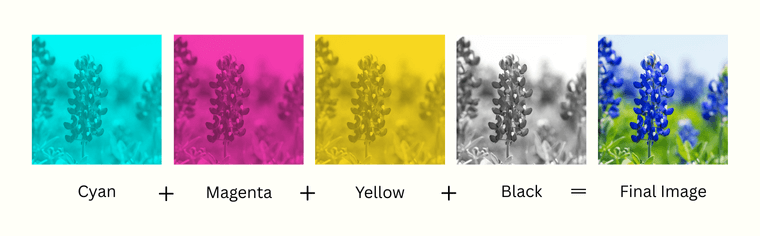

The drums, one each for cyan, magenta, yellow, and black (CMYK), spin up and receive an electrostatic charge. Depending on the model, the drum may be fully charged and then selectively discharged, or vice versa. This charge is what allows the laser or LED to “draw” your image onto the drum.

4. Laser or LED Imaging

A laser beam or LED array shines onto the drum in the exact shape of your print. Where the light hits, it changes the charge, essentially creating an invisible stencil of your image.

5. Toner Development

The developer assembly comes into play next. Inside, a magnetic roller spins through a mix of developer (tiny steel beads) and toner powder. Toner sticks to the beads, which then roll past the drum. The drum’s charge attracts the toner where your image has been “drawn,” leaving the developer beads behind to be reused.

6. Onto the Transfer Belt

The toner image moves from each drum to the transfer belt. This is a loop that carries all four CMYK images in perfect alignment. A bias transfer roller on the other side of the belt uses an opposite charge to pull toner from the drum onto the belt. This is where precision matters: optical sensors check small calibration marks (“chevrons”) made during cleaning and adjust alignment down to fractions of a millimeter.

7. Paper Registration

While all this is happening, your sheet of paper is pulled from the tray and squared up in the registration unit. This ensures the image will be perfectly straight on the page.

8. Transferring to Paper

The paper passes between the transfer belt and a second bias transfer roller, which flips the charge on the toner again so it’s attracted to the paper instead of the belt. Now your image is on the sheet, but the toner is still loose and powdery.

9. Fusing

The paper rolls through the fuser unit, which is like two heated rollers. These get very hot. They get hot enough to melt the toner particles so they bond permanently to the paper fibers. It’s sort of like a laminator, but with toner instead of plastic film.

10. Output

Your finished page slides onto the output tray, dry to the touch, smudge-proof, and ready to use.

Key Components Working Together

Here’s a quick reference list of the parts doing the heavy lifting:

- Drums – One per color, holds the electrostatic image.

- Transfer Belt – Carries and aligns the CMYK layers.

- Developer Assembly – Mixes toner with developer beads for transfer.

- Bias Transfer Rollers – Moves toner from drum to belt and belt to paper.

- Fuser – Heat and pressure to seal the image.

- Xerographic Processing Board – Controls the timing and accuracy.

Want to learn about other printer-related definitions? Check out our blog: 64 Printing Terms Defined

How Color Laser Printers Differ from Other Printers

- Monochrome laser printers have just one drum and skip the transfer belt, sending toner straight to the paper.

- Inkjet printers spray wet ink directly onto paper, making them slower for large volumes and more expensive per page.

Learn more about the difference between laser and inkjet printers here.

How Printers Get Color Accuracy Right

Those calibration chevrons we mentioned earlier? They’re tiny test marks the printer lays down during cleaning. Internal sensors read them and adjust the position of each color layer so they stack perfectly. That’s why a modern color laser can print complex graphics with razor-sharp edges.

Common Myths About Color Laser Printers

- “They use the laser to burn the image onto paper.” Incorrect. The laser only changes the charge on the drum, whereas the fuser handles the heat.

- “They’re slow to warm up.” Many modern models start printing in seconds.

- “They’re too expensive for small offices.” The upfront cost is higher than that of an inkjet, but the cost per page is much lower, especially if you print a lot.

Why It Matters for Businesses & Schools

For high-volume printing, speed and cost efficiency are critical. A color laser printer:

- Prints faster than inkjet for bulk jobs.

- Handles heavy workloads without breaking down.

- Offers lower long-term cost per page.

- Produces sharp, consistent quality, even for thousands of pages.

If your organization prints marketing materials, reports, or any high-volume color jobs, a color laser printer can pay for itself quickly.

Find the Best Printer for Your Needs

Now that you know exactly how a color laser printer works, you can choose one that fits your budget, space, and workload. We’ve already done the homework. Check out our recommendations here: The Best Laser Printers for Home Use in 2025.

Or, if you need additional help, check out our blog on How to Choose a Printer for Your Budget.